Erxleben Gmbh si affida a VISI e simula con Stampack

cortesia Mecadat AG L’attrezzeria del fornitore automobilistico Erxleben Verformungstechnik ha convertito parzialmente il CAD e completamente combiato il CAM con VISI. Da allora l’azienda di Wildeshausen è stata in grado di agire in modo più rapido e flessibile, anche… Per saperne di più

VISI “The Best For Toolmaking”

“Switching to VISI has proved to be a huge step forward as it is tailored specifically for tool making, offering all the functions we need in the sheet metal industry.” “I can now do everything in CAD without being concerned… Per saperne di più

Two-Impression Tool Made Through VISI Helps School’s COVID-19 Plan

Rutland Plastics moulds 25,000 headbands for visor masks An injection moulding specialist helped a public school in Rutland to produce thousands of pieces of PPE for frontline workers during the early days of the COVID-19 crisis. While Oakham School was… Per saperne di più

VISI Expansion Helps Medical Manufacturer in COVID-19 Fight

Free Temporary License Means XL Precision Could Increase Production Immediately. Expanding its suite of VISI software has enabled a medical components specialist to increase its capacity by up to 40 per cent, dedicating that additional production to manufacturing parts to… Per saperne di più

VISI Helps Mouldmaker Rise To New Challenges

Having revamped their corporate image and website in the last few weeks, an injection mould manufacturer welcomes new challenges, and is pushing ahead with important medical, aerospace and automotive contracts. Alpha Precision say they push the boundaries of what’s possible… Per saperne di più

VISI Provides Highest Technical Solution For QDM Specialist

A Quick Delivery Mould (QDM) specialist says Draft Analysis is an important time saver for their business, and has played a major contribution towards meeting customers’ increasingly faster turnaround demands. Based at Incheon in South Korea, Polyhitech Co. Ltd. use… Per saperne di più

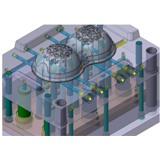

VISI Optimises Flow for Medical Device

VISI Optimises Flow for Medical Device Thin Wall Section Needed for Flexibility with 38 Nodules A toolmaker and injection moulder was tasked with developing a potentially life-saving medical device; and then designing and machining a complex steel mould tool with… Per saperne di più

VISI Helps mould makers create small complex parts

“Specialist says VISI means moulds should be called “advanced equipment”. A mould maker producing tools for thermoplastic materials and die-castings relies on the specialist VISI Analysis module to discover critical areas at an early stage of the design process, which… Per saperne di più

Non-Parametric Design From VISI Benefits Brandauer’s

VISI overcomes design issues for a 156-year-old precision stamping company, enabling them to ship around 150-billion individual products a year. With a strapline of “From Pens to Particle Physics,” Brandauer was established in 1862, originally producing pen nibs. It has… Per saperne di più

VISI – a “Good Mate” for Injection Mold Maker

A plastic injection mold maker says it guarantees full reliability for its customers, thanks to the role that specialist VISI software plays in its design and manufacturing processes. CMP Bresso produces molds for a variety of industrial sectors, including automotive,… Per saperne di più