VISI “The Best For Toolmaking”

“I can now do everything in CAD without being concerned about the model source or data history.” Those are the words of a stamping and forming toolmaker, explaining what VISI software means to him.

“That’s a huge advantage for me, because I can give my full attention to the tool,” says Stefan Schmitz, who, with two colleagues, is responsible for designing progressive dies and equipment at Franz Pauli.

“The VISI philosophy of a ‘one source solution,’ coupled with its ease of use, and the functions its modules provide for tool design, and which are precisely co-ordinated to the sheet metal area, play a significant role in us being able to respond even faster and more flexibly to today’s demanding customer requirements.”

Franz-Bernd Pauli, Managing Director

The company, based in Ense-Parsit, Germany, use specialist tools on their 40 eccentric and 17 hydraulic presses which manufacture inserts with a pressing force of up to 6000 kN. In addition, they have 18 stamping machines with a pressing force of around 4000 kN. These are provided with steel strips up to 6 mm thick, and coils reaching a width of 800 mm. In subsequent production steps some of the batches are deburred with others being spot-welded or TIG-welded. This is, for example, how complex formed furniture fittings, pre-finished frames for sliding roofs in cars, and complete impellers for fitness trainers, are created.

Managing Director Franz-Bernd Pauli says: “Our greatest strength is working closely with customers from the start of a project right through to series production. This includes the prototype development and our expertise in tool making. It’s important to have a consistent software solution enabling us to react quickly, flexibly and smoothly at every stage, right through to completing the production-ready tool.”

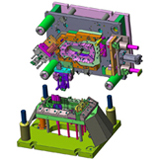

When Stefan Schmitz joined Franz Pauli he felt the parametric system previously used by the company was ideal for mechanical engineering, but not for tool making. “Switching to VISI has proved to be a huge step forward as it is tailored specifically for tool making, offering all the functions we need in the sheet metal industry.” That consistent sector-orientated alignment, coupled with its milling strategies and EDM functionality, along with technical support from VISI reseller MECADAT, led to the company to transfer completely to VISI. Currently, Franz Pauli are running three CAD workstations in the design office and a full CAD/CAM workstation in the production area with 2D, 3D milling and Wire EDM.

“As a combined surface and solid modeller, VISI supports me as a tool designer with detailed tailored functions and automated algorithms for the design process. When I use VISI I can always focus on the entire tool, as it doesn’t have a complicated parametric structure. This means I can be much more flexible without worrying about the assembly hierarchy. For example, if I do want to work on the details I can always thin out the tool.”

But VISI proves its worth even before the contract has been won; at the quotation stage. “At this point the 3D CAD model of the customer’s part is nearly always available. Regardless of the native CAD format, we can import into VISI and check out the dimensions. Then I create a blank, position the strips and determine the strip width. From this, we calculate the cost of both the tool and the part.”

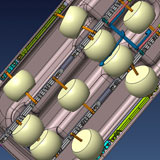

He says the blank then forms the basis for the pre-calculation of the tool, and he uses the method planning later for the full tool design where the 3D strip layout is constructed using VISI Progress, and is passed to the bending station, where the tool is constructed.

Once the tool has been designed, the strip layout is updated using the bending and drawing stages. “VISI makes it easy to try out different paths to find the optimum process. I can graphically animate the forming process, making it easy to assess material wrinkling and thinning, highlighting any possible fracture points.”

The parts making up the tool are measured against the 3D CAD model, and the final blank is created in the tool by wire erosion. The tool is then brought to the press, measured again, and if tolerances have been maintained, production begins.

Technical Manager Oliver Fischer, who is responsible for the CAD strategies, says that as design engineers no longer stand at the milling machines, the operators must also be able to understand and operate the system. “VISI is so easy to use – which I consider to be another great strength.”

Each machine operator creates the NC programs in the tool making department, and uses VISI Machining to establish which components will be brought together in one process. “As VISI uses the same CAD model for design and NC programming, the data’s consistency and interoperability is guaranteed. This is a major advantage for the actual programming and if any modifications are required – two significant aspects of tool making.”

The software also plays a key role on the shopfloor with VISI’s Compass Technology generating considerable time savings. Automatic feature recognition algorithms independently detect regular geometry such as edges, holes and milling pockets, then automatically generates the necessary NC data, maintaining company standards and ensuring proven manufacturing methods.

Franz-Bernd Pauli concludes: “The VISI philosophy of a ‘one source solution,’ coupled with its ease of use, and the functions its modules provide for tool design, and which are precisely co-ordinated to the sheet metal area, play a significant role in us being able to respond even faster and more flexibly to today’s demanding customer requirements.”

About the Company

Name: Franz Pauli Gmbh & Co. KG

Web: www.pauli-ense.de

Benefits Achieved

- Single software solution for quoting, forming analysis, 3D tool design, and CNC manufacturing.

- Sheet metal forming analysis to identify potential issues such as material wrinkling and thinning.

- Guaranteed data consistency and interoperability as single source model used for both CAD and CAM operations.

Comments

“The VISI philosophy of a ‘one source solution,’ coupled with its ease of use, and the functions its modules provide for tool design, and which are precisely co-ordinated to the sheet metal area, play a significant role in us being able to respond even faster and more flexibly to today’s demanding customer requirements.”

Franz-Bernd Pauli, Managing Director